Shaping the future means increasingly developing smart and intelligent products and services in the construction machinery sector as well.

A milestone in engine development

With the E1 technology, the first electronic control system for single-cylinder diesel, Hatz presented a milestone in engine development. It bridges the gap between mechanically controlled engines and the requirements of modern, digitized companies. E1 technology paves the way for handheld machines, mobile light poles and power generators to be brought into the era of the Internet of Things (IoT). For the first time, the prerequisites for digital solutions in this device class have been met.

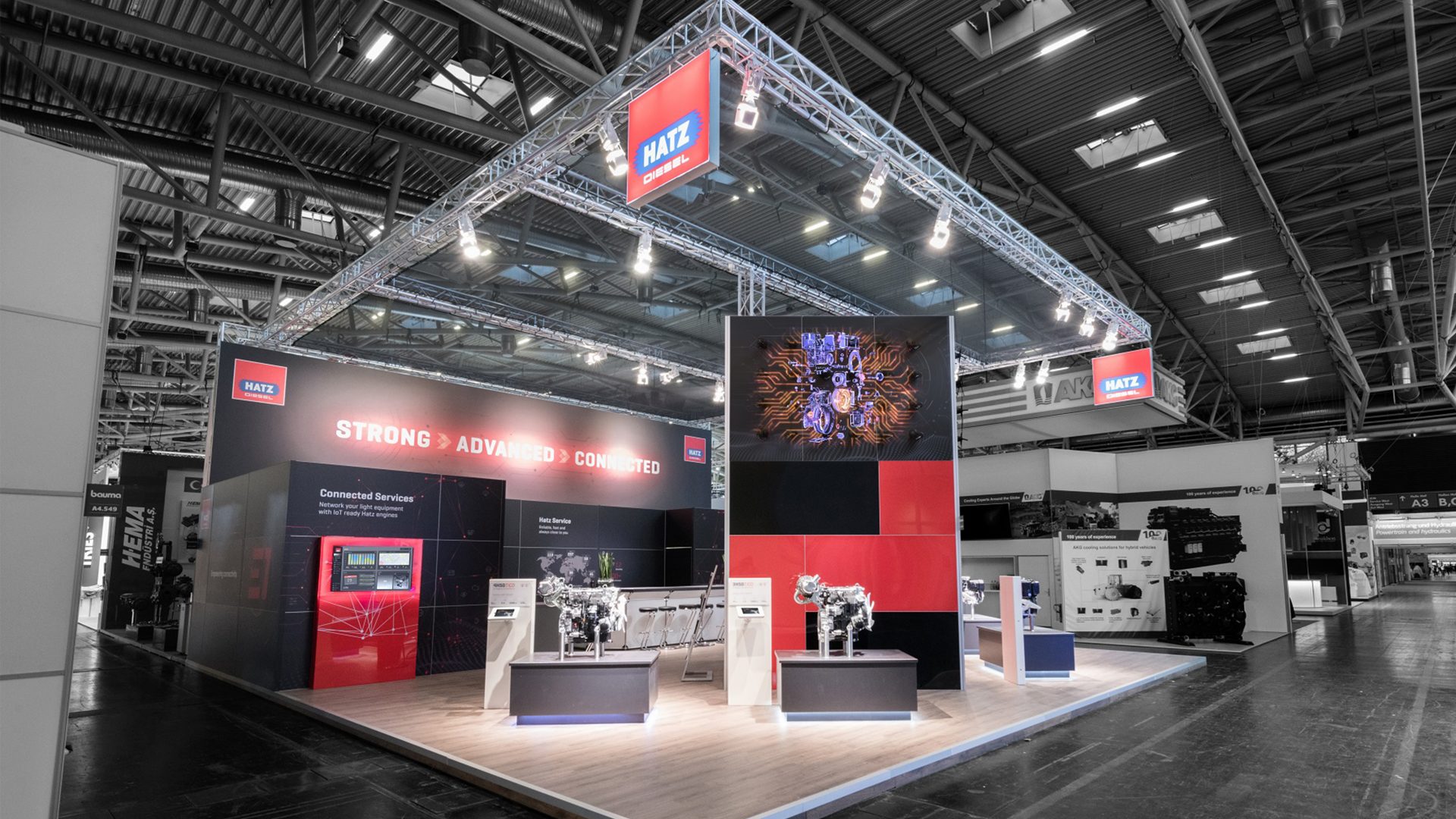

Strong. Advanced. Connected.

Another innovation was Hatz Connected Services, the network of digitally controlled motors with innovative applications such as cloud based platforms or apps.

Visitors were able to test an app developed by HYVE together with Hatz for monitoring, locating, maintaining and organizing motors directly at the exhibition stand. In addition to a status overview, which provides information on the status of the motors (active, in maintenance, inactive or defective), engine availability, operating hours, daily and weekly use, engine load, locations, maintenance phase and repair status can also be displayed. Detail views allow a very accurate and complete view of the engine without having it in your hands. The app not only shows engine speeds, fill level, oil, intake and exhaust temperatures, but also the soot load or battery voltage, to name just a few parameters.

HYVE’s researchers were still gathering direct user feedback at bauma: After clicking through, users of the app were able to fill out a virtual questionnaire directly at the stand, in which the overall impression, interactivity, functionality, usability, visual design could be evaluated and wishes for an app could be expressed. The results will help to optimize the app and to develop further innovative offers.

What a Connected Service App could look like Hatz developed together with HYVE in an Ideation Workshop, from which vision, needs of different players, idea generation and clustering were transformed into concepts.

It is remarkable how visibly digitization is changing and shaping this traditional and down-to-earth industry. From the autonomous vibratory plate, which moves between trade fair visitors without a person operating it, to intelligent excavator shovels, which indicate the weight of the load to the operator, to the software developed together with Hatz in Ideation Workshops.

Shaping the future means increasingly developing smart and intelligent products and services in the construction machinery sector as well. As the world’s leading diesel engine manufacturer, Hatz has its finger on the pulse with its product revolutions.

Markus Rieger, former Managing Director at HYVE

It is essential not to miss the puls at a time of globalization and internationalization, in which new business models and innovative ideas will be decisive for competition – also for engine manufacturers. We thank Hatz for the exciting project and are happy about its success!